13,606 parts - one passion

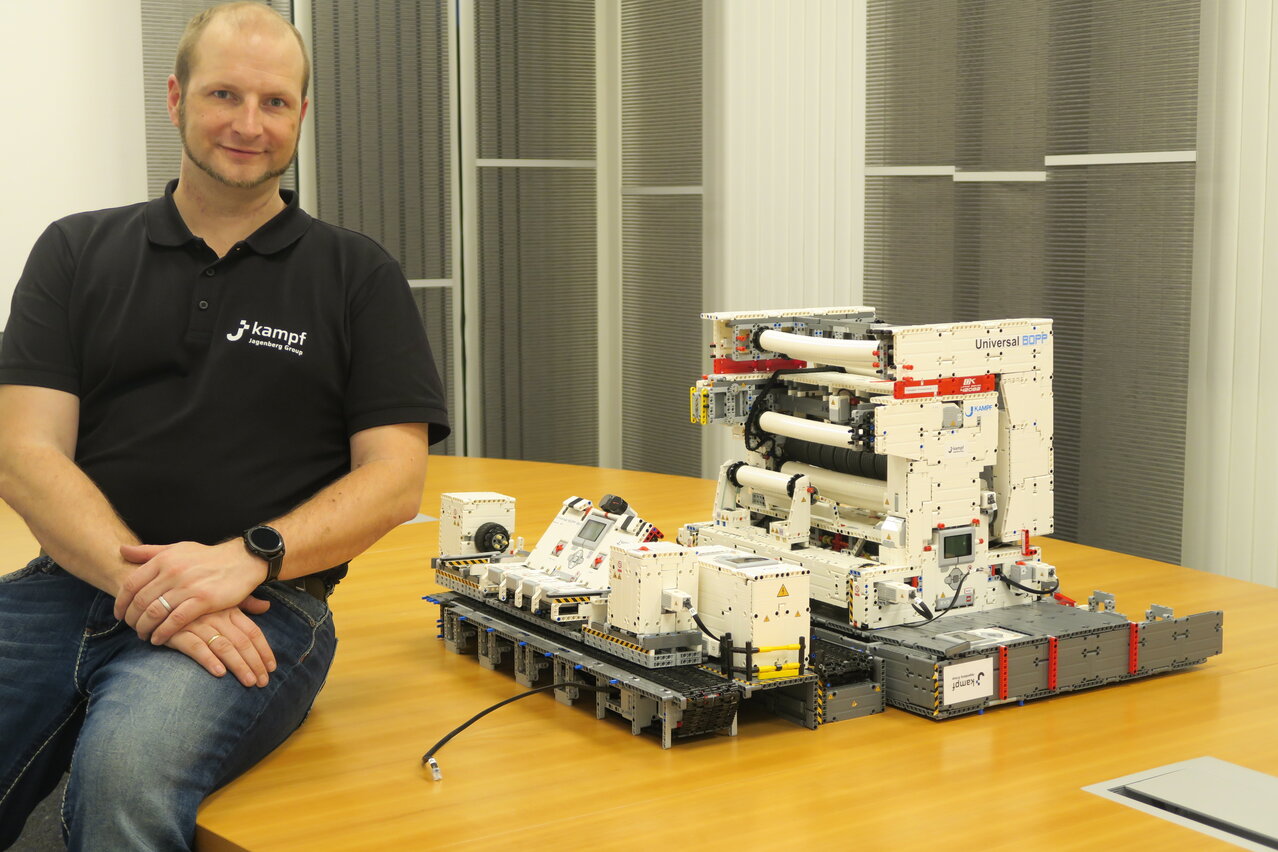

True passion for his work: for Björn Moritz from Kampf Fieldservice, that's almost an understatement. The cutting machines he installs around the world fascinate the 40-year-old so much that he builds them to scale and fully functional – out of LEGO®.

"LEGO® Technic is a line from the terminal block manufacturer LEGO® that features primarily complex and advanced functions. These include gear trains, pneumatic components as well as electric motors. Thus, LEGO® Technic goes far beyond the mere play function of the original LEGO® bricks and opens up creative possibilities for tinkerers like Björn Moritz."

Big technology in small format

The idea to recreate one of the Universal BOPP cutting machines, like the one he oversees at Fieldservice, first came to Björn Moritz in 2019. "LEGO® Technic" models of cutting machines that student project groups had built, were on display in the training workshop, the so-called "Wissenswerk," of Kampf Schneid- und Wickeltechnik GmbH. "I can do that too – and maybe even much better," the machinist said to himself at the time. "And that's how the passion developed."

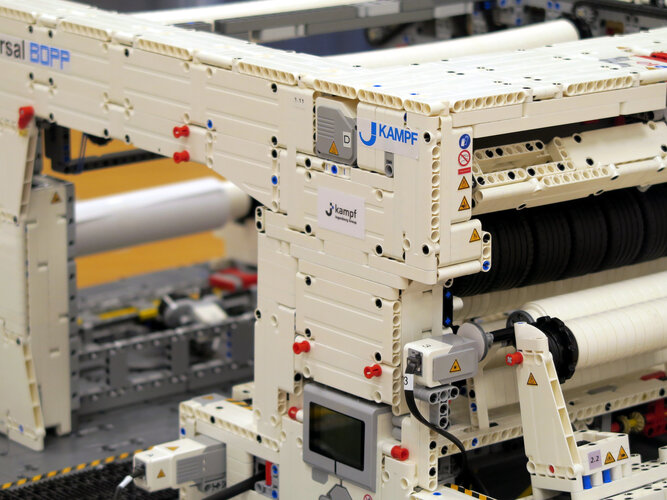

As a result, the first machine was made from the Danish plastic bricks in his living room at home. From memory, Mr. Moritz constructed a detailed copy of a Universal BOPP cutting machine using LEGO® Education and Mindstorm sets. Complementary "LEGO® Technic" models such as "bucket-wheel excavators" completed the plant in miniature before he put it into operation after electrical equipment and programming. But this was only the beginning: "The feedback from colleagues was a challenge for me to develop the model further," the tinkerer confesses.

"The feedback of the colleagues was a challenge for me to further develop the model."

Björn Moritz,

Machinist

An upgrade that will amaze even professionals

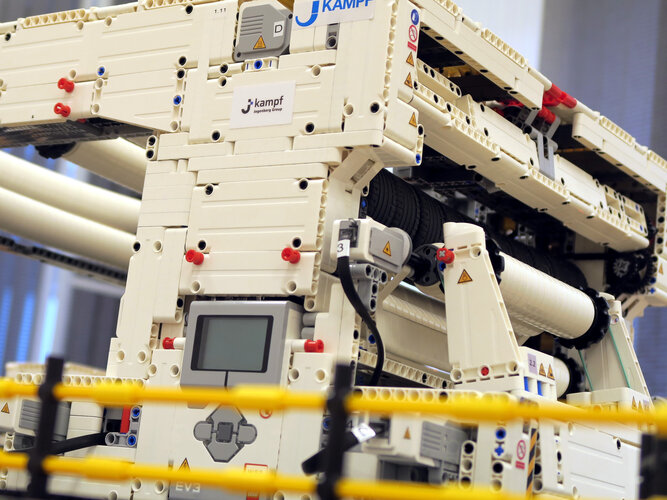

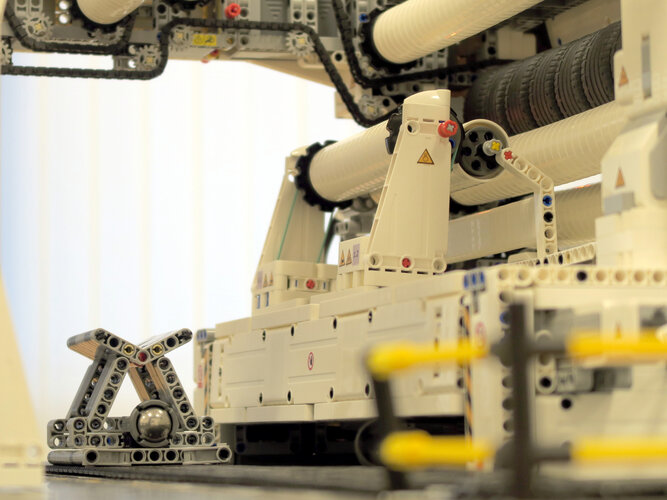

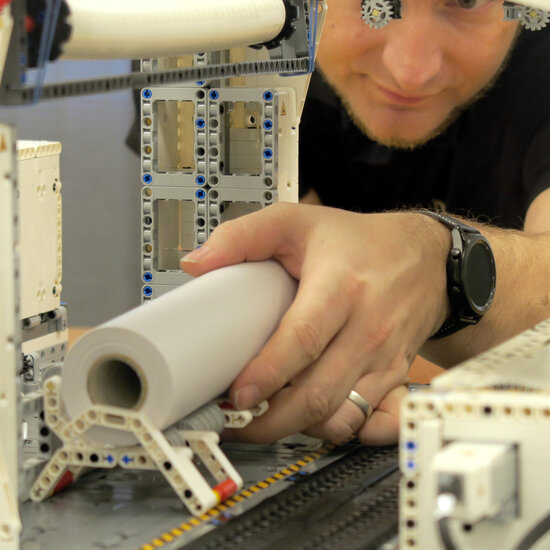

While his first machine included non-LEGO® elements, such as cardboard tubes from a real Roll-o-Fix cutting machine, the new machine is "LEGO® Technic" in its purest form. Instead of a CAD system, Björn Moritz relied on the digital LEGO® construction kit "Bricklink Studio 2.0". For the construction, he developed pre-assemblable building units and specially designed foundation plates, which enabled him to shorten the assembly time. The modular design enables short assembly and disassembly times and thus easier transport of the cutting machine, which weighs around 17 kg. Björn Moritz replaced the cardboard rollers inside the machine with corresponding LEGO® bricks. For these and for the white paint, he had to order bricks individually.

Thus, with great attention to detail, a 1.20 meter long, 80 cm wide and 40 cm high machine was created, which caused astonishment up to the top floor of the store: "It was not only the true-to-the-original functionality that impressed me," admitted Kampf Managing Director Lutz Busch when he inspected the machine. "Even the elaboration of the warning and safety pictograms is simply amazing. We are proud and happy to have such competent and creative employees on board!"

It is difficult to measure in figures how much know-how and, above all, passion such a complex project requires. But a construction period of almost eight months and 13,606 parts speak for themselves, giving an idea of the effort involved in conceptual considerations, material procurement, assembly, programming, transport and documentation. "It's hard to give Mr. Moritz's commitment enough credit, and we look forward to what's to come," noted Managing Director Busch, who presented his employee with an iPad in appreciation. And Björn Moritz is also looking forward to improving his work even more: "This was my first project and I'm absolutely motivated for more!" So it remains exciting ...