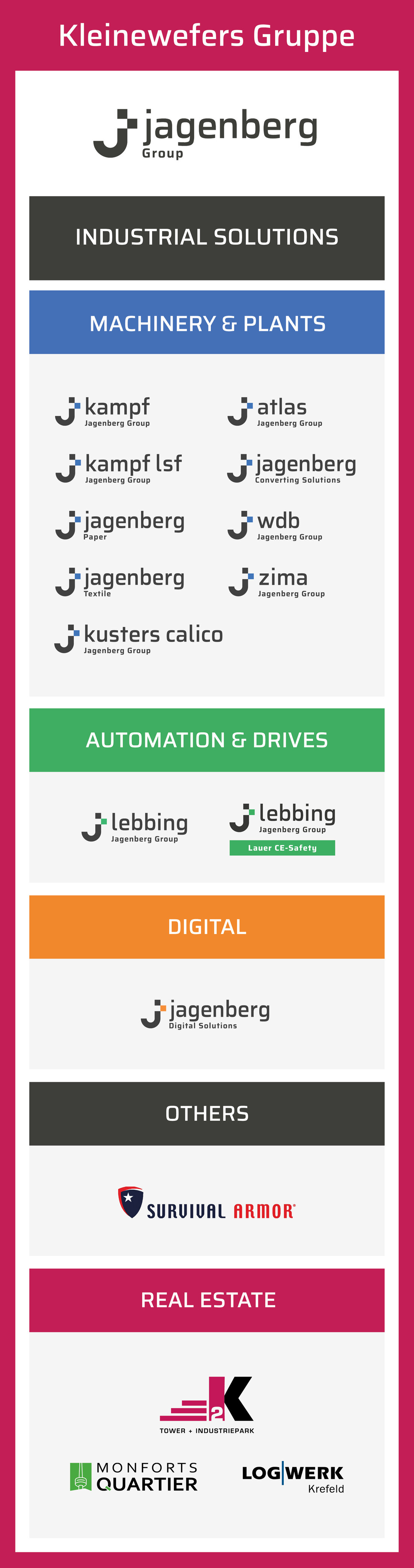

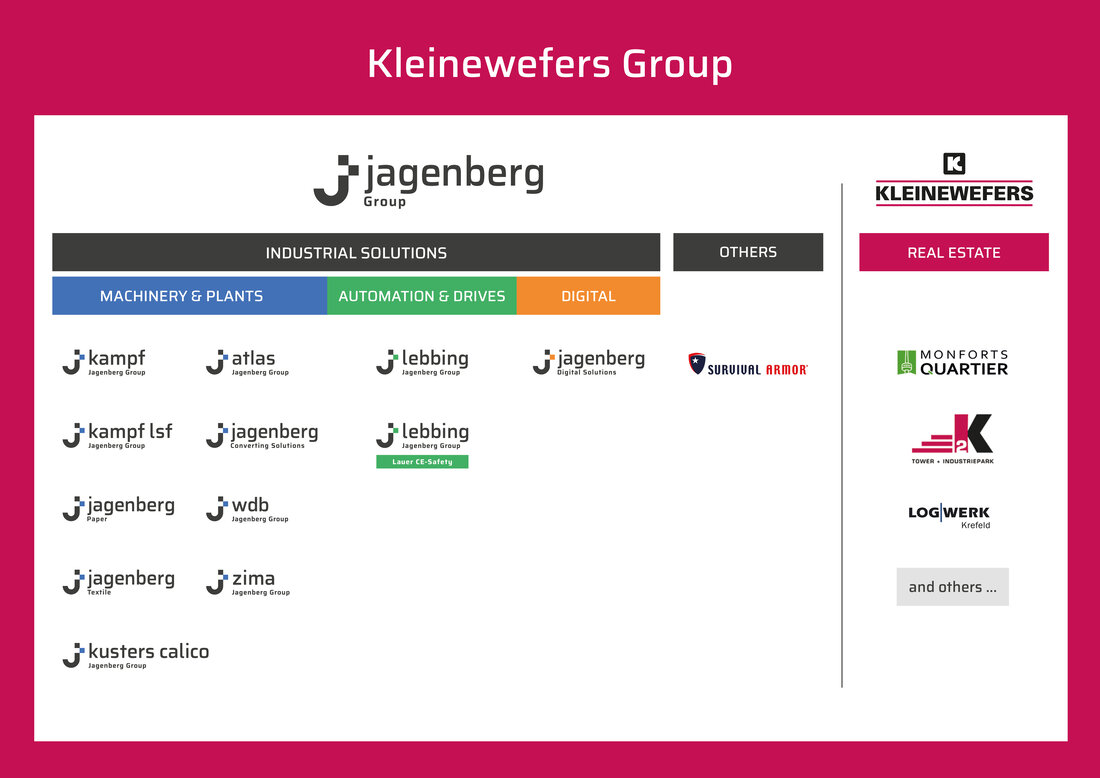

THREE BUSINESS AREAS - ONE GOAL

By focusing on the three business areas Machinery & Plants, Automation & Drives and Digital, we are pursuing the overarching goal of developing solutions with a high technological standard in Jagenberg Group. Digitalization plays a key role in generating new products and business models that meet the current and future requirements of our customers.

Jagenberg Group - solutions for a variety of applications.

Jagenberg Group takes care of sustainable and innovative solutions.

Machinery & Plants

The historical roots of the Jagenberg Group lie in mechanical engineering, which is still the largest business area of our group of companies today. Based on our extensive experience, we develop solutions for processing and finishing web materials, tailored to the specific requirements of customers in a wide range of industries - from slitting and winding machines to coating, printing or dyeing machines.

Hand in hand with our customers, we develop both standard solutions and tailor-made systems that set standards and form the basis for long-term partnerships. In doing so, we always remain open to the development of new fields of application and possibilities.

Automation & Drives

As a partner to machine builders and operators, our Automation & Drives business area is characterized by its ability to provide comprehensive, solution-oriented advice to customers in a wide range of industries. Our core competence is drive, control and automation technology for machines and systems for processing web materials.

The aim is to develop custom-fit solutions for efficient production processes - also for current and future challenges of Industry 4.0. To this end, we support our customers from conceptual design and project planning throughout the entire project lifecycle to after-sales service. In addition to solutions for new plants, a second focus of our work is on the modernization and optimization of existing machine technology (retrofit) and the application of converting technologies.

Digital

The focus of the Digital business area is on optimizing and increasing the efficiency of companies across the entire production process. As one of the leading providers of digital solutions, we are pursuing a holistic approach with the integrative platform we have created, the@vanced. This complements the existing digital offering of the Jagenberg Group with more advanced requirements of our customers as well as new partners from related industries.

To this end, we are working intensively on new digital products for the future topics we have defined. This includes intensive collaboration within the Jagenberg Group as well as partnership and investment in promising startups and cooperation with universities and external partners.

As a specialty machine builder with more than 100 years of experience, Kampf LSF develops solutions for processing and finishing web-shaped materials. Tailor-made to meet the high requirements of demanding industries, Kampf LSF develops and adapts both near-standard components and machines as well as individually designed systems.

Jagenberg Converting Solutions supplies turnkey solutions for finishing demanding web-shaped materials from a single source. The portfolio includes solutions for printing, varnishing and coating. Here, the company focuses on extremely demanding applications for technical films from the decorative printing and lithium-ion battery sectors.

The company WDB Systemtechnik GmbH is an owner-managed, medium-sized company and has been based in Herford (Enger) NRW since 1995. Since then we have been dealing with machines for the paper, foil and printing industry. We have set our main focus especially in machine and plant construction.

Emerging from a German-Indian joint venture with bundled know-how, Kusters Calico is one of the leading suppliers of machinery and equipment for textile wet finishing. The company, based in Vadodara, India, also designs, builds and sells coating and laminating lines for the packaging industry.

With digital products and services, Jagenberg Digital Solutions creates added value in production. The integrative IIOT platform the@vanced offers manufacturers from a wide range of industries a powerful basis for digital communication between machines and planning systems, serves as an enabler for data-based services and thus ensures efficiency in manufacturing.

As a specialty machine builder with more than 100 years of experience, Kampf LSF develops solutions for processing and finishing web-shaped materials. Tailor-made to meet the high requirements of demanding industries, Kampf LSF develops and adapts both near-standard components and machines as well as individually designed systems.

The company WDB Systemtechnik GmbH is an owner-managed, medium-sized company and has been based in Herford (Enger) NRW since 1995. Since then we have been dealing with machines for the paper, foil and printing industry. We have set our main focus especially in machine and plant construction.

Emerging from a German-Indian joint venture with bundled know-how, Kusters Calico is one of the leading suppliers of machinery and equipment for textile wet finishing. The company, based in Vadodara, India, also designs, builds and sells coating and laminating lines for the packaging industry.

Jagenberg Converting Solutions supplies turnkey solutions for finishing demanding web-shaped materials from a single source. The portfolio includes solutions for printing, varnishing and coating. Here, the company focuses on extremely demanding applications for technical films from the decorative printing and lithium-ion battery sectors.

TO JAGENBERG CONVERTING SOLUTIONS

As a specialist in service, retrofitting and mechanical engineering, Jagenberg Paper stands for high-quality, custom-fit solutions in paper finishing. Based on decades of experience, the company develops innovative concepts for modernizing winders, calenders and sheeters. In the new machine segment, the focus is on winders and calenders.

Jagenberg Converting Solutions supplies turnkey solutions for finishing demanding web-shaped materials from a single source. The portfolio includes solutions for printing, varnishing and coating. Here, the company focuses on extremely demanding applications for technical films from the decorative printing and lithium-ion battery sectors.

TO JAGENBERG CONVERTING SOLUTIONS

Emerging from a German-Indian joint venture with bundled know-how, Kusters Calico is one of the leading suppliers of machinery and equipment for textile wet finishing. The company, based in Vadodara, India, also designs, builds and sells coating and laminating lines for the packaging industry.

The mainstay of the US subsidiary Zima is equipment for efficient wastewater treatment and for textile and carpet finishing. As a high-end developer and manufacturer, the company, which is one of the world's leading producers of dyeing and finishing equipment, specializes in particular in stainless steel plants.

Jagenberg Textile manufactures and upgrades wet finishing equipment for woven and knitted fabrics and has a first-class reputation among customers in Europe and South America. On its way to becoming one of the leading solution providers, Jagenberg Textile's portfolio includes textile dyeing machines as well as bleaching, mercerizing and washing lines.

Slitting and winding technology from Kampf has been contributing to the high-quality production and processing of web-shaped materials for many decades. As a competence leader, the company drives technological developments and intelligently links its machines with upstream and downstream processes through automation and digitalization.

As a specialty machine builder with more than 100 years of experience, Kampf LSF develops solutions for processing and finishing web-shaped materials. Tailor-made to meet the high requirements of demanding industries, Kampf LSF develops and adapts both near-standard components and machines as well as individually designed systems.

Jagenberg Converting Solutions supplies turnkey solutions for finishing demanding web-shaped materials from a single source. The portfolio includes solutions for printing, varnishing and coating. Here, the company focuses on extremely demanding applications for technical films from the decorative printing and lithium-ion battery sectors.

TO JAGENBERG CONVERTING SOLUTIONS

As a specialist in service, retrofitting and mechanical engineering, Jagenberg Paper stands for high-quality, custom-fit solutions in paper finishing. Based on decades of experience, the company develops innovative concepts for modernizing winders, calenders and sheeters. In the new machine segment, the focus is on winders and calenders.

Atlas Converting Equipment Ltd. was established in 1976 and is a world leading supplier and provider of solutions in slitting and rewinding technology and finished roll handling systems. The Atlas and Titan brands are recognised as global market leaders in the production of primary and secondary slitter rewinders with over 4,000 machine installations in over 80 countries around the world.

Slitting and winding technology from Kampf has been contributing to the high-quality production and processing of web-shaped materials for many decades. As a competence leader, the company drives technological developments and intelligently links its machines with upstream and downstream processes through automation and digitalization.

As a specialty machine builder with more than 100 years of experience, Kampf LSF develops solutions for processing and finishing web-shaped materials. Tailor-made to meet the high requirements of demanding industries, Kampf LSF develops and adapts both near-standard components and machines as well as individually designed systems.

As a specialist in service, retrofitting and mechanical engineering, Jagenberg Paper stands for high-quality, custom-fit solutions in paper finishing. Based on decades of experience, the company develops innovative concepts for modernizing winders, calenders and sheeters. In the new machine segment, the focus is on winders and calenders.

Jagenberg Converting Solutions supplies turnkey solutions for finishing demanding web-shaped materials from a single source. The portfolio includes solutions for printing, varnishing and coating. Here, the company focuses on extremely demanding applications for technical films from the decorative printing and lithium-ion battery sectors.

TO JAGENBERG CONVERTING SOLUTIONS

The planning, design and installation of drive and automation technology as well as data systems is closely associated with the name Lebbing. The portfolio of the innovative company includes project planning and realization of drive and automation technology for new plants as well as modernization and optimization (retrofitting) of existing machine technology.

Emerging from a German-Indian joint venture with bundled know-how, Kusters Calico is one of the leading suppliers of machinery and equipment for textile wet finishing. The company, based in Vadodara, India, also designs, builds and sells coating and laminating lines for the packaging industry.

Slitting and winding technology from Kampf has been contributing to the high-quality production and processing of web-shaped materials for many decades. As a competence leader, the company drives technological developments and intelligently links its machines with upstream and downstream processes through automation and digitalization.

The planning, design and installation of drive and automation technology as well as data systems is closely associated with the name Lebbing. The portfolio of the innovative company includes project planning and realization of drive and automation technology for new plants as well as modernization and optimization (retrofitting) of existing machine technology.

With digital products and services, Jagenberg Digital Solutions creates added value in production. The integrative IIOT platform the@vanced offers manufacturers from a wide range of industries a powerful basis for digital communication between machines and planning systems, serves as an enabler for data-based services and thus ensures efficiency in manufacturing.

The planning, design and installation of drive and automation technology as well as data systems is closely associated with the name Lebbing. The portfolio of the innovative company includes project planning and realization of drive and automation technology for new plants as well as modernization and optimization (retrofitting) of existing machine technology.

Slitting and winding technology from Kampf has been contributing to the high-quality production and processing of web-shaped materials for many decades. As a competence leader, the company drives technological developments and intelligently links its machines with upstream and downstream processes through automation and digitalization.

Jagenberg Converting Solutions supplies turnkey solutions for finishing demanding web-shaped materials from a single source. The portfolio includes solutions for printing, varnishing and coating. Here, the company focuses on extremely demanding applications for technical films from the decorative printing and lithium-ion battery sectors.

The company WDB Systemtechnik GmbH is an owner-managed, medium-sized company and has been based in Herford (Enger) NRW since 1995. Since then we have been dealing with machines for the paper, foil and printing industry. We have set our main focus especially in machine and plant construction.

Jagenberg Converting Solutions supplies turnkey solutions for finishing demanding web-shaped materials from a single source. The portfolio includes solutions for printing, varnishing and coating. Here, the company focuses on extremely demanding applications for technical films from the decorative printing and lithium-ion battery sectors.