Interviewing Martin Partikel: “The Groupʼs turnkey solutions enable us to take full advantage of market opportunities.”

Martin Partikel, 34, joined Kampf LSF GmbH & Co. KG in September 2022 as Head of Sales. The family man from Leipzig takes a fresh look at the company and gives an insight on the upcoming Hannover Messe 2023.

Mr. Partikel, how would you describe your tasks and topics at Kampf LSF?

As Head of Sales, my primary goal is to ensure the future of the company. Developing new customers and areas of interest, as well as consolidating our pillars of business, are among my tasks. The development of a clever sales strategy that contributes to the expansion and strengthening of our market position is therefore enormously important. My team and I are always working on customer loyalty and ensuring that competitive products and solutions are launched on the market.

Another very exciting field for me is the extension of cooperation with the other companies in the Jagenberg Group. I really enjoy developing turnkey solutions in which our products play a role, and this always makes for an interesting exchange of experiences.

You are a trained automotive mechatronics technician and then studied industrial engineering with a specialization in mechanical engineering; so technology has always played a major role in your life. What excites you so much about mechanical and plant engineering?

I always found it exciting to implement economic tasks and consequently solve other people's problems. That's exactly what we do here at Kampf LSF every day: We don't just build a machine or plant, but we help the customer find a solution. I think that's great!

Moreover, in this industry you are involved in product development from the very beginning and experience all phases very intensively. I have been working in custom machine construction since 2012 and find it highly exciting! From the inquiry on a blank sheet of paper, the communication and support of the customer, to the construction of the machine and the after-sales service. That's how you accompany a project over several years.

We don't just build a machine, we help the customer find a solution. I think that's great!

Martin Partikel,

Head of Sales at Kampf LSF GmbH & Co. KG

In the middle of April, you will be exhibiting the EvoSlitter at the Siemens booth at the Hannover Messe, and will be representing the Jagenberg Group there. How did the collaboration come about and what will you be demonstrating at the trade show?

Hannover Messe is the world's leading trade fair for the industry, where more than 4000 companies from different economic sectors are expected to be present in 2023. This year, the focus is on solutions for a networked and climate-neutral industry. At the Siemens booth, we as the Jagenberg Group are allowed to exhibit a product from the company group. We have chosen the EvoSlitter from Kampf LSF, because this product is used in the field of battery production.

At the trade show, our focus will be on the close cooperation with the global player Siemens and the potential benefits that result from the collaboration for both companies. Thanks to Siemens' software, we can, for example, carry out virtual commissioning and thereby save costs and time in the future. We can use the software to test certain processes while they are still in the production phase, which gives us a clear competitive advantage.

I will be directly on site during the trade show and will be available as a contact person. There is no doubt that I am proud to be able to exhibit one of our machines at such an important trade show.

Let's continue with the EvoSlitter. What are the special features of this machine?

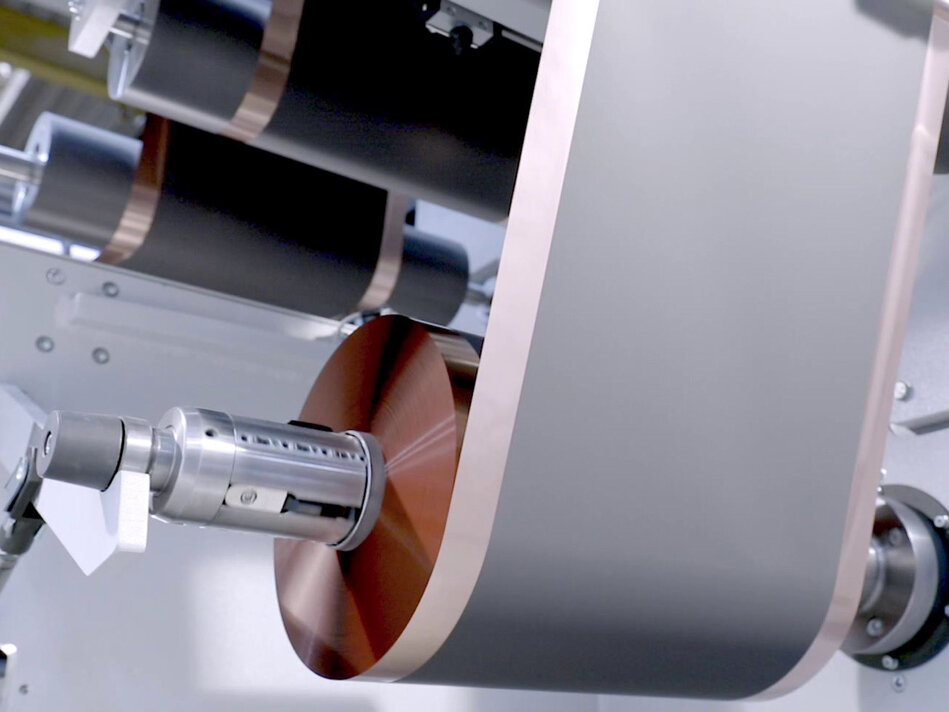

The EvoSlitter is specially designed for slitting cathode and electrode materials of lithium-ion batteries and supercapacitors. This highly complex machine is designed for working widths up to 800 mm and realizes speeds up to 150 m/min. Materials coated on one side as well as on both sides can be processed with continuous as well as intermittent coatings.

Due to the very compact design and the associated low space requirement, the EvoSlitter is particularly suitable for use in pilot plants, but meanwhile also in productive production lines. The highest demands on slitting qualities and winding accuracies are met. Thanks to the high number of options, such as cleaning, inspection and changing systems, we succeed in combining flexibility and productivity. These features ensure that the machine absolutely meets the special requirements of battery and supercapacitor production.

As part of the Jagenberg Group, you benefit from the advantages of such a cooperation. What exactly does this mean for you and Kampf LSF?

The combination of the companies creates great opportunities for us. There are currently huge market opportunities in the energy and surface sectors for web-shaped materials, which we can only seize together with our turnkey solutions, bundled by Jagenberg Converting Solutions GmbH. We can benefit from the knowledge, network and expertise of the other companies in the Jagenberg Group and become even better as a result. We manage to generate synergies. I have only been in the Group for six months, but I can already see that our motto "Create.Future.Together." is really being lived! We are merging more and more and you can just see the development towards joint projects! I am looking forward to the future together in the Jagenberg Group!